Ceramic Substrates and Packages for Automotive LEDs

Automotive LEDs require thermal protection and high reliability. Kyocera offers high-thermal-dissipating, high reliability ceramic packages and substrates for automotive LED applications, including headlights.

Features

Higher Thermal Dissipation

IATF 16949 Certified

Various Thin Film Options

For High-Reliability, High-Current Applications

For High-Reliability, High-Current Applications

Design Flexibility for Cavity Structures

Easy Resin Potting

Easy Resin Potting

Our packages and substrates are IATF16949 certified with a proven track record of supporting automotive applications.

*IATF16949: An international standard for quality management systems in the automotive industry, developed by the International Automotive Task Force.

Single-Layer Substrate + Thin Film

A sample of Aluminum thin film process

- Kyocera tailors film configurations to meet customer requirements. For example, the aluminum thin film process is available for Al wire-bonding requirements.

Check other available film configuration options here. - For traceability, each piece can be serialized with laser marking.

Multilayer Substrate + Thin Film

- Thin-film processing is available on the surface of multilayer substrates

- High-density, 3-D electrical routing is possible with a multilayer ceramic structure

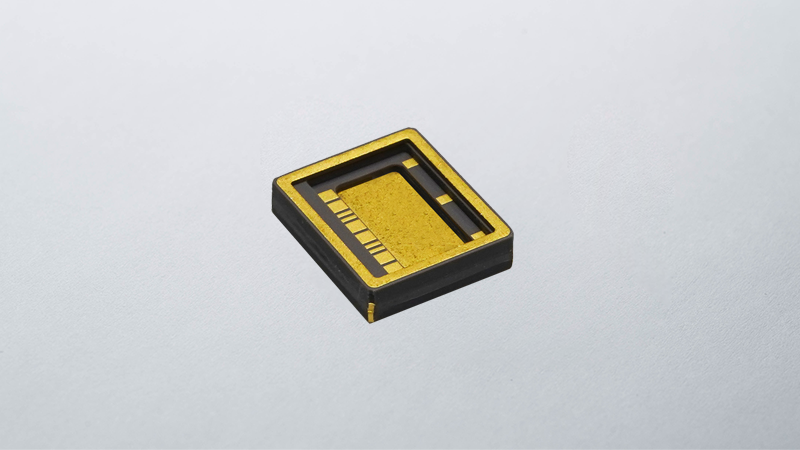

Surface-Mount Multilayer Packages

Structure / Concept (Alumina / Aluminum Nitride)

Round Cavity

Square Cavity

Hermetic Sealing

Stepped Structure for Lid Placement

(Cross-Section)

Easy lid placement for sealing

Easy lid placement for sealing

Angled Cavity

(Cross-Section)

Cavity walls serve as reflectors.

Cavity walls serve as reflectors.

With Heat Spreader

(Cross-Section)

Cu fittings optimaize heat dissipation. (Alumina Only)

Cu fittings optimaize heat dissipation. (Alumina Only)

FAQ

Solutions

Applications

Materials

Technologies